23.09.2022

Managing Component EOL

GD Rectifiers’ Managing Director, Paul Bentley offers advice on mitigating risks when facing end-of-life issues

What advice would you offer purchasers faced with component obsolescence?

The easiest way to manage component obsolescence is to partner with an experienced and knowledgeable distributor that will proactively help source hard-to-find components or offer a suitable alternative. It’s important that a distributor can offer multiple products from various manufacturers, to ensure pricing and lead times do not affect the supply chain.

GD Rectifiers holds inventory in the UK and stock an extensive range of power electronic components, including semiconductor components, circuit protection devices, passive components, magnetic transducers and wound products. We have long standing relationships with the brands we stock and speak to the factories daily. We are working closely with our entire network of suppliers to ensure we continue servicing our customers during this busy period and throughout this global pandemic.

How has the demand and scope for replacement components changed over the last 12 months?

We have seen a huge increase in lead times and so far this year we’ve already seen two price increases from several of our manufacturers.

Some of the world’s leading semiconductor manufacturers are experiencing unprecedented production challenges caused by many factors including: raw material shortages, US/China trade war, Covid-19 and extreme weather.

As a result, a large number of customers have been willing to explore alternative parts over the past year, instead of waiting for a 26+ week lead time. Customers are also starting to consider replacement parts if the need to switch arises, pre-empting production issues and delays with their regular components and planning for all eventualities. GD Rectifiers has been best placed to support customers on alternative parts and managing component EOL due to their wealth of semiconductor experience and broad product range.

When faced with component obsolescence, what time-frames do purchasers have before securing last time buys?

As soon as we receive PCNs (product change notices) or PDN (product discontinuation notices) we notify our customers of the relevant changes of the products we stock via our blog. We publish all PDNs, including last time buys and replacement parts where possible, usually within 48 hours of receiving them directly from the manufacturer. Usually our manufacturers give customers at least 4-8 week’s notice on last time buys but they can often provide up to 3 month’s notice.

It is crucial that purchasers work with a distributor that can support them on data analytics, risk mitigation and product life cycle. Distributors can advise the best components to use for new designs and tell them which ones to avoid. As soon as a purchaser becomes aware that a component is being made obsolete, they should collaborate with their distributor to source an alternative supply, confirming availability and pricing.

GD Rectifiers has been distributing power electronic components for over 57 years, their extensive product portfolio and proficient technical expertise has provided an unrivalled, friendly shopping experience for their customers.

Semiconductor Components – diodes, high voltage diodes, MOSFETs, discrete IGBTs, IGBT modules, thyristors, inverter modules, gate turn-off thyristors, thyristor module accessories, thyristor diode modules, rectifier bridges, TVS diodes, optically isolated AC power switches, switchable current regulators, gate drivers, SiC power MOSFETs and SiC schottky diodes.

Circuit Protection Devices – semiconductor fuses, fuse mountings, battery storage fuse links, high speed fuses, high voltage fuses, IEC and British Standard fuses, Industrial fuses, medium voltage fuses, industrial power and UL fuses, low voltage UL and CSA branch circuit fuses, specialty fuses, resettable PTC fuses, square body fuses, EMI filters, DC filters, RFI filters, Harmonic filters, medical and military filters, parallel filters, motor protection, power factor correction, DV/DT, varistors, surge protection modules, surge arresters, selenium transient suppressors, breakover diodes, thermal trips and LED protectors.

Passive Components – EMC/EMI/RFI filters, resistors, capacitors and low and ultra low temperature capacitors.

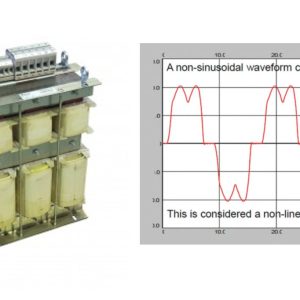

Power Supplies & Transformers – current and voltage transformers, pulse HF and current transformers, current transformers, inductors, line reactors, single phase transformers, three phase transformers and transformer and Mu metal cores.

Traction Converters and Subsystems – converters for coaches, converters for locomotives, converters for trains, converters for Trams, liquid cooling systems, power electronic building blocks and trackside converters.

Power Assemblies and Controllers – power assemblies, rectifiers, regulators, firing circuits/trigger modules, selenium suppressors, rotating diode assemblies, photovoltaic triple diode assemblies, blocking and voltage dropping diodes, selenium rectifiers, single phase assemblies, three phase assemblies and hex phase assemblies.

Heatsinks and Hardware – heatsink extrusions, closed loop water coolers, forced air cooled heatsinks, water/oil cooled heatsinks, LED heatsinks, CNC machining, clamps for capsules, busbar insulators, busbars for modules, AC and DC axial fans, thermal trips, water to water heat exchangers and thermal compound.

Renewable Energy – LED lighting, LED lighting surge protection, wind power, solar arc flash detection, solar cells and modules, solar power, solar protection arrays, solar protection relays, solar rated varistors, solar surge protection devices, solar TVS diodes, surface mount LED protectors and photovoltaic triple diode assembly.

For further information on GD Rectifiers product range please click here or to discuss your enquiry, please call our sales team on: 01444 243 452 / [email protected].