28.07.2017

Semikron’s MiniSKiiP – 20 Years of Innovation

Published on: 28/07/2017

Semikron’s MiniSKiiP power modules were launched 20 years ago

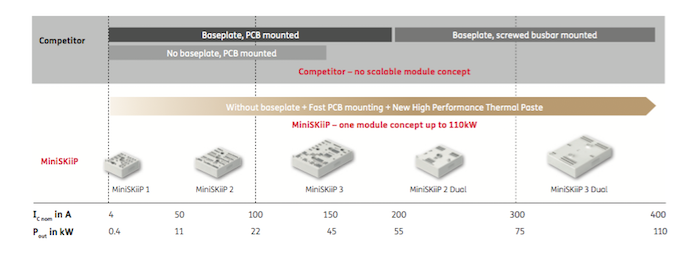

Semikron’s MiniSKiiP modules offer a unique design, setting a new standard in the power electronics industry. They are designed for 600V/650V, 1200V and 1700V with 4A-400A nominal chip currents. The modules are solder-free PCB assembly using spring contacts, easy PCB design and high reliability resulting in a cost benefit.

Today, there are more than 35 million modules in the field, it was the first module available with pre-applied thermal interface material, one of the first industrial standard modules with Silicon Carbide (SiC) and is the only module to cover a power range from 1 to 90kW as a full motor drives solution.

Semikron continue to innovative the future, MiniSKiiP boosts reliability and power density and it is now finding its way to new markets such as medium-voltage inverters.

Semikron packaging technologies optimise thermal resistance layering between the chip and heatsink, the output current capability and power density is increased by more than 30% while using the same physical chipset and power module size.

Semikron’s MiniSKiiP: The Benefits

One of the main benefits of MiniSKiiP modules is the easy assembly and service-friendly spring-contacts for the load and gate terminals. No special tools are required for a MiniSKiiP assembly, the PCB (printed circuit board), power module and heatsink are all assembled in one mounting step using a one or two step screw connection.

Applications

The MiniSKiiP modules are used in numerous applications such as: standard drives, stand-alone drives, servo drives, system drives, solar inverters, UPS systems and welding machines.

GD Rectifiers is an official European distributor for SEMIKRON, they have been distributing their products for over 50 years.

Discover more about how using Semikron’s packaging technologies could improve your product performance today. Call us on: 01444 243 452 or email: [email protected]