20.09.2016

September 2016 – GD Rectifiers’ High Efficiency Heat Sinks

Published on: 20/09/2016

High efficiency heat sinks utilise aluminiums excellent natural heat conductivity properties to dissipate heat in many everyday applications such as renewable energy, transport, and power electronics requiring high density cooling of power devices.

Cooling principle

The efficiency of a heatsink is determined by surface area and proximity to the power source. So a large number of fins of optimal length and enhanced surface area with controlled spacing is desirable. Generally, 10-12mm spacing for natural convection, but much closer for force air cooling. GD Rectifiers high efficiency range achieves both objectives. Resulting in weight saving, high density, compact and efficient power cooling designs.

For free air convection cooling, surface area and free air flow volume are the primary factors in the heat sinks efficiency. Increasing either or both improves the heat sink’s efficiency and reduces its thermal impedance. The most common heat sink design factor which influences the thermal performance is the material that the heat sink is made from. The most common heat sink material today is Aluminum because it has higher thermal conductivity values.

The most commonly used interface material in the electronics cooling area is thermal compound, a sticky paste which is applied directly on to the heat sink or CPU. A good-quality thermal compound will provide the best possible performance.

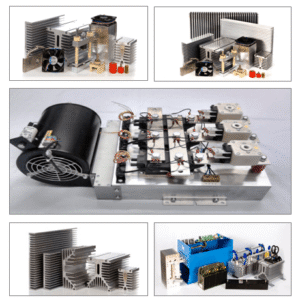

High Efficiency Heat Sinks – Typical examples:

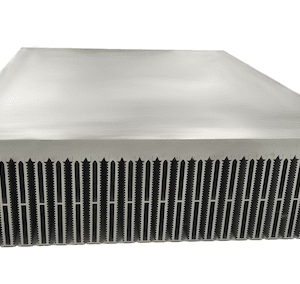

Heat sinks with solid fins

Application: A solid fin heat sink is designed for free convection; however, it can also be used for forced-air cooled systems as well.

Heat sinks with hollow fins:

Application: A hollow fin heat sink is exclusively designed for use with forced-air cooled systems. Serrations assist turbulent air at higher velocities.

GD Rectifiers is the UK’s leading manufacturer of standard and custom made heatsinks, heat sink accessories and heat sink assemblies. They stock and machine the largest range of heatsinks suitable for stud, modules and capsule semiconductors plus high power LED applications. Offering a full service from design to production, technical support and fast delivery, GD Rectifiers is the No.1 heat sink provider in the UK.

At GD Rectifiers, we’re experts in thermal management, standard & custom made heat sinks, cold plates, liquid cooling solutions and thermal assemblies. Offering an extensive range of air cooled and aluminium heat sinks, we have a wide selection of high quality heat sinks readily available in stock at unbeatable prices and offer a next day delivery service.

Browse the complete heat sink range by device type, part number or comparison guide here. At GD Rectifiers, we also offer technical support on all heat sinks including specific heat dissipation requirements.

For further information on all heat sink products click here or alternatively call our friendly sales team for a quote today on: 01444 243 452.

Find out more about the latest GD Rectifiers product range here.