21.07.2020

A Simplified Heatsink Design Process

Published on: 21/07/2020

With the demand for more cost-effective solutions, it’s time to simplify the heatsink design process

GD Rectifiers understands that no heatsink project or requirement is rarely the same, which is why they offer a comprehensive range of heatsink services and solutions, designed with customers in mind.

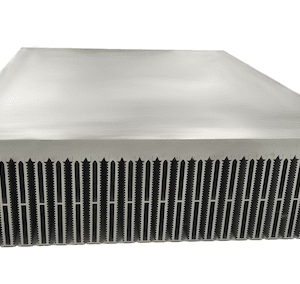

GD Rectifiers offer a diverse range of standard heatsinks, including: aluminium heatsinks, forced air-cooled heatsinks, LED heatsinks, water and oil cooled heatsinks, solid fin heatsinks and hollow fin heatsinks.

GD Rectifiers stock over 160 heatsink profiles in stock and offer a large range of services, including: CNC machining, extrusion and deburring. They also offer a large range of heatsink accessories, including: clamps for capsules, busbar insulators, busbars for modules, AC and DC axial fans, thermal trips and thermal compound.

GD Rectifiers works with customers directly on custom heatsink specifications, including size, profiles, deburring and finishing options. GD Rectifiers offers customers a bespoke and cost-effective service, by providing customised cooling solutions.

GD Rectifiers offers the following thermal consulting services to simplify the heatsink design process

1. Custom drawings

GD Rectifiers can work to an existing drawing or they can act as part of your design team or even as an independent design resource. Our engineers are ready to assist customers at any stage of the process to help identify the best thermal solution for your product.

2. CNC Machining

We offer a precision CNC machining and milling service at our factory in Burgess Hill. Our dedicated machinery is used purely for machining heatsink to bespoke outlines specified by customers.

We are able to skim, drill and tap any heatsink from our range to customer specifications, no matter how complicated the design. Our CNC machines are up to 1000m with a saw capacity of 500mm x 200mm.

3. Existing extrusion in stock

We have a vast range of experience in heatsinks and ensures sufficient aluminium extrusion for our most popular profiles are in stock at all times.

4. Modifying existing heatsink profiles in stock

Depending on how quickly customers need heatsinks and depending on the quantity required, our design engineers might suggest modifying an existing heatsink in stock to meet the required delivery date.

GD Rectifiers would always suggest manufacturing a customised heatsink where possible, to give the best representation of the profile, however modifying an existing profile from stock is also an option.

5. Heatsink samples

GD Rectifiers can provide heatsink samples, whether you need just one or a batch of 20 initially. We can provide samples from stock or manufacture customised heatsinks. When requesting samples, it is always recommended to tell us what your predicted forecast is, along with any delivery schedules you have in mind. This helps our sales team to put together a quote based on your sample request and for your on-going requirements.

For further information on GD Rectifiers’ heatsink range or to request a sample, please call the sales team on: 01444 243 452 or email: [email protected]. Don’t forget to follow us on LinkedIn to learn more about our heatsink products and services.