17.11.2016

Cooling Techniques for Specialised Electronics

Published on: 17/11/2016

Find the right cooling techniques for specialised electronics

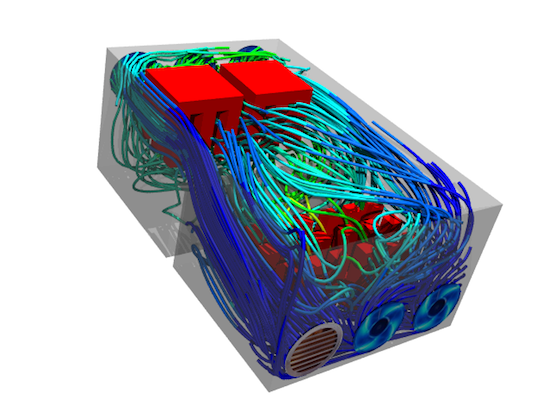

Forced Convection Caedium CFD Simulation shows streamlines colored by temperature, photo credit: symscape.com

Cooling Techniques for Specialised Electronics

All electronic devices generate heat but the higher the efficiency rating of the device, the less internal heat is generated within it. The generated heat must be dissipated to maximise the end products reliability and prevent premature failure. One of the main focal points of the design process of an electronic application is the cooling technique.

Conduction Cooling

Conduction cooling is the transfer of heat from one hot part to a cooler part by direct contact. Many DC-DC converters have a flat surface that is designed to mount directly to an external heat sink or cold plate that will conduct the heat away from the power device by direct contact which then cools it.

The majority of power supplies use internal heat sinks that are in contact with power devices via a thermal conductive paste or pad to conduct away from the heat. The heat sinks rely on convection cooling to transfer their conducted heat to the cooler surrounding air.

Convection Cooling

Convection cooling involves the transfer of heat from a power device by the action of the natural air flow surrounding the the unit remains within a limited temperature range that is cooler than the device. One of the main advantages of convection cooling is that no fans are required.

The use of fans can reduce the mean-time-between-failure ratings of power supplies. Convection cooling works best when the products have a natural circulating source of air.

Heat generating electronic devices like DC-DC converters, microprocessors and hybrid circuits usually require the heat sink to facilitate convection cooling and to assist in transferring the heat away from the devices to the cooler air. Heat sinks utilise both conduction and convection cooling and are designed to dissipate heat.

Radiant Cooling

Radiant cooling is the transfer of heat by electromagnetic radiation that flows from a hot object. Radiant heat transfer does not require air and takes place in applications such as a vacuum.

Thermoelectric Coolers

Thermoelectric coolers are solid-state devices that function similar to heat pumps. TECs require an external DC power source to operate them. The power device to be cooled is mounted on one side of the TEC with an appropriate thermal grease of thermal pad when a voltage is applied to the TEC, the heat is pulled away from the power device and pumped to the opposite side that has a heat sink. Thermoelectric coolers are effective but have low efficiencies and are more expensive than heat sinks or fans. They are used to cool laser diodes, ultra-fast microprocessors and laboratory instruments.

Liquid Cooled Cold Plates

Liquid cooled cold plates are usually comprised of aluminium or copper plates on which the power devices are mounted that contain parallel ducts or serpentine tubes through which a liquid coolant is pumped and then routed to an external heat exchanger where the liquid is then cooled.

The majority of cooling techniques used today are utilised in power semiconductor and microprocessor devices, with new ones added daily. Each of these active devices are specified to operate safely within a certain temperature range that must not be exceeded.

Semiconductor internal junction temperatures cannot be measured directly, so devices such as MOSFETs, DC-DC converters and power bricks are specified to operate safely as long as its metal case, mounting tab or baseplate temperature is kept below the specified maximum.

GD Rectifiers designs and manufactures Selenium and Silicon Rectifiers, Suppressors, Converters, Inverters, Regulators and all other power products for Industrial power control applications. The company distributes state of the art Diodes, Thyristors, IGBTs and MOSFETs from the world’s leading manufacturers including: IXYS, IXYS UK Westcode, Semikron and EDI.

GD Rectifiers manufacture an extensive range of power components and assemblies. The company also supplies a wide range of Heat Sinks suitable for Power Semiconductors, LED Lighting and similar applications. GD Rectifiers also offer a repair and replacement service for faulty or ageing Semiconductor Rectifiers, Converters, Inverters and Regulators.

For further information on all GD Rectifiers products click here or contact our sales team on: 01444 243 452 / [email protected].